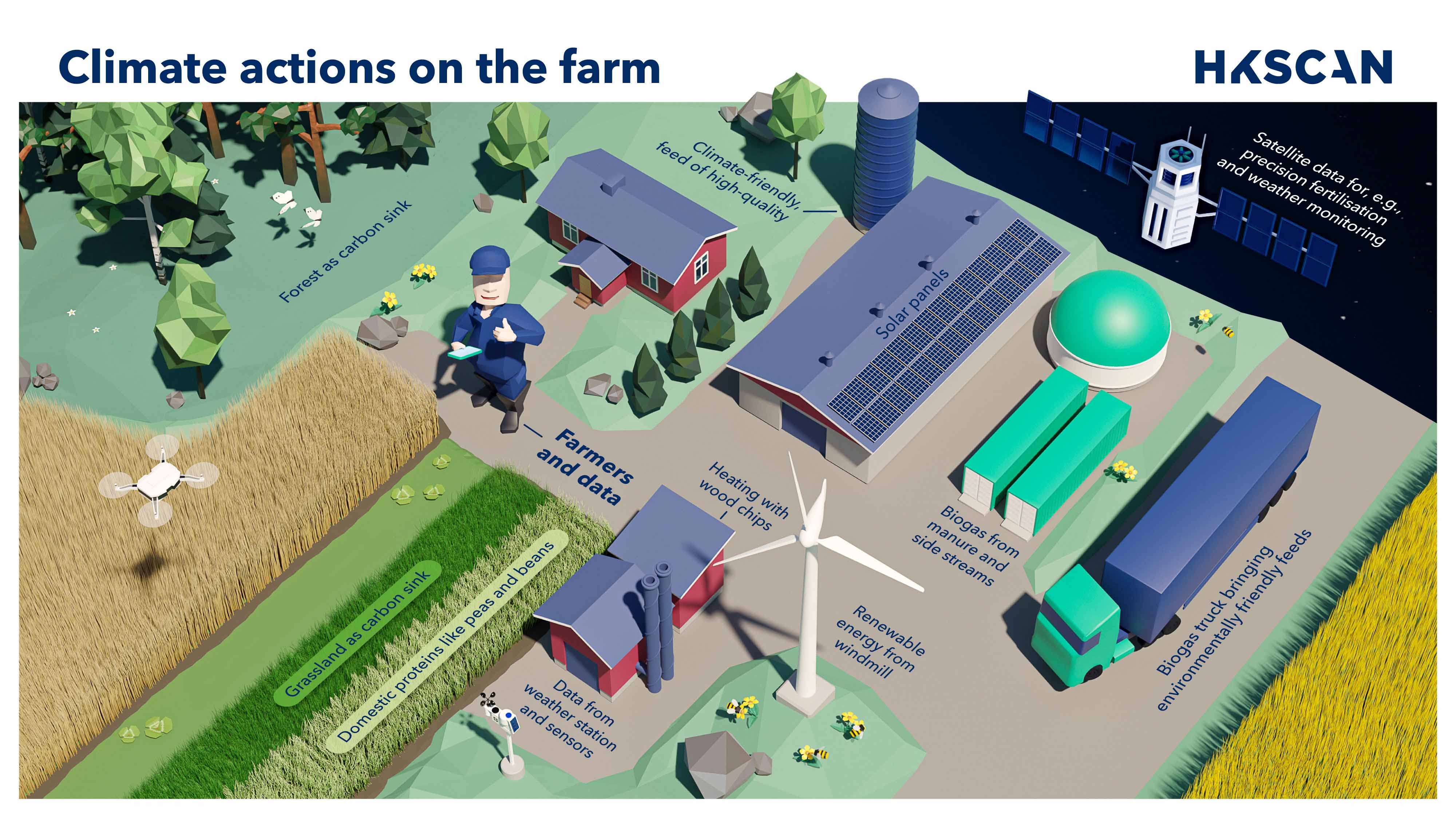

Our target is to develop our food chain from farms to consumers also from environmental perspective. New ways of producing food are part of the solution to climate change. Our climate actions reduce emissions and increase carbon sinks.

Together with our contract farmers and other partners, we are moving towards our target. In primary production, we focus on reducing emissions from feed production and land use, which have a major impact on climate. Promotion of resource efficiency and carbon sequestration in field farming are at the heart of our efforts.

Our priorities of the climate plan in reducing the environmental impact of agriculture:

- We reduce the climate impact of animal feed production by optimising the use of fertilisers and other production inputs.

- We promote carbon sequestration in the fields together with our partners.

- We develop conditions for more effective circular use of manure, for example in energy production or as a fertiliser.

- We invite our contract producers to join our climate training and provide tools to develop more sustainable meat production.

HKScan’s contract farms have long worked to reduce the climate impact, for example by increasing the circular use of manure, introducing solar power and promoting resource efficiency in feed production.

Reducing emissions from primary production requires diverse expertise, so in addition to us and our contract farmers, other companies as well as expert and research organisations will be involved. Together, we will look into new ways to reduce climate impacts and scale good practices across our home markets with an ecosystem-based operating model.